Generative AI and Aluminum Electrolytic Capacitors

2023 is thought of as the “year of generative AI” due to the full-scale adoption of the technology in various industries. Since ChatGPT by OpenAI was released in November 2022, generative AI has been the focus of significant attention.

Generative AI also puts a spotlight on semiconductors, particularly graphics processing units (GPU), but how has this impacted the passive components produced by Nippon Chemi-Con (hereinafter, we/our Company)?

Passive components

Examples of parts that receive, store, discharge, and consume energy (electricity) from external sources include capacitors, coils, and resistors.

In contrast to passive components, components which have amplification *1 and rectification *2 functions, such as semiconductors and vacuum tubes, are called active components.

- Amplification: Passing a current through one electrode, causes a large current to flow between other electrodes.

- Rectification: Current flows in a single direction, with no current flowing in the opposite direction.

Generative AI and electronic components

Generative AI requires a large-scale computing environment because it learns and generates by processing billions of parameters.

Semiconductors called AI accelerators are used to process a large number of parameters in parallel. For this task, it is common to use components such as GPUs, which can perform parallel processing on a larger scale than traditional central processing units (CPUs).

Personal devices (PCs, mobile terminals) are also equipped with semiconductors that support "neural networks," machine learning that mimics the human brain network. The use of generative AI in image processing and other applications is advancing. However, large-scale generative AI uses systems stored in data centers connected through networks.

What is a data center?

A data center is a facility where a large number of computers are installed in a dedicated building or space and can be accessed from a remote location. In most cases, data centers are established in buildings built specifically for the purpose. Also, due to the high level of security required, the general public rarely has a chance to see the inside of these facilities.

These facilities are not limited to generative AI, and continues to expand in scale due to the increasing use of cloud services.

Web services and content operated by many companies and individuals, including our own website, are provided via cloud services or in-house equipment installed in data centers. It is also likely that individuals are unknowingly using cloud services for social media and for storing images.

Data center equipment

We hope the information provided thus far provides an understanding of how data centers are indispensable facilities not only for conventional uses such as cloud services, but also for newly emerging uses such as generative AI.

So, what types of equipment are installed in data centers? Let’s take a look at the sites using the electronic components we offer.

The semiconductors used in CPUs and GPUs will not operate without direct current voltage. This is because the structure of a semiconductor is a sandwich structure comprised of two types of materials (p-type and n-type), and the direction in which current flows is fixed.

Modern semiconductors are characterized by low operating voltages and large currents. The following equipment is used to receive power from high-voltage power lines and create DC voltage suitable for semiconductors.

Explanation of terminology

1kV means 1000V. Just as 1kg is 1000g, this is a unit of measurement.

The description Vac indicates the alternating current voltage.

The description Vdc indicates the direct current voltage.

For example, an alkaline battery has a voltage of 1.5Vdc, which means a DC voltage of 1.5V.

Note: The voltages listed in this article are commonly used in the U.S.

Power reception equipment

Receives 138kV and 67kV, which are called special high voltages, from high-voltage power lines.

Circuit breaker

A circuit breaker is a device that disconnects power receiving equipment from the power distribution system (power transmission lines, etc.).

This switch has a special structure that reliably cuts off voltages exceeding 10kV and does not cause arc discharge (sparks).

Transformer

Inside the data center, transformers are used to convert 138kV/67kV, which are extra high voltages, into the 120-277Vac range used in server systems in three stages.

- Transformer stage

- 1) 138k/67kVac → 7.2kVac

- 2) 7.2kVac → 600/480Vac

- 3) 600/480Vac → 120-277Vac

Uninterrupted power supply(UPS)

Equipped with a battery to enable continued operation for a certain period of time even in the event of a power outage.

Power supply(AC/DC)

Converts 120-277Vac to 12Vdc or 48Vdc direct current.

Server on-board power supply(POL)

Converts electricity to a voltage used by each internal component.

GPU-adjacent power source(POL)

Can handle large currents despite having a low voltage of roughly 1Vdc.

Follows immediately even if the load fluctuates.

We will explain in detail about these facilities and the equipment in which aluminum electrolytic capacitors are used.

1. Circuit breaker

The circuit breakers used in places where high voltage is received from power transmission lines are called vacuum circuit breakers or gas-insulated circuit breakers. A large capacity aluminum electrolytic capacitor is used so that it can be turned off in an emergency even if the power is lost.

2. Power supply(AC/DC)

Converts alternating current electricity into direct current while also adjusting power to the appropriate voltage. It's easy to understand if you imagine something familiar like an AC adapter or USB charger. (For USB chargers in U.S., AC 120Vac is converted to DC 5-20Vdc. Output is 5-100W.)

In data centers in U.S., 240/277Vac is normally supplied to racks with integrated server units. This is converted to 12V/48Vdc and supplied to the servers. The power consumption varies depending on the type of server, but typically systems range from a few hundred watts to 1kW. With server systems for generative AI, there are millions of systems using over 10kW. *3

(A hair dryer is roughly 1kW, so you can imagine that servers use a very large amount of electricity.)

Power supplies for servers are housed in limited rack space, so they must be designed to fit into very tight spaces. Our aluminum electrolytic capacitors are used in power supplies to achieve rectification *4 and output retention *5. With the ultra-high output models for generative AI, the aspect ratio is long in the vertical direction, thus high capacitance aluminum electrolytic capacitors are being used with increasing regularity.

Example of vertical (long L) aluminum electrolytic capacitor

- Wattage per power supply. It is common for a rack to contain from a few to 10 or more power supplies.

- Rectification: Rectification in a power supply device means converting alternating current to direct current. Semiconductors (diodes) and capacitors are used to convert alternating current, which has a constantly fluctuating voltage, into direct current, which has a constant voltage.

- Output retention: The output voltage is maintained even when the outlet voltage momentarily drops due to the influence of peripheral equipment or when the power required on the server side changes suddenly. This is achieved by supplying electricity stored in a capacitor.

Reference

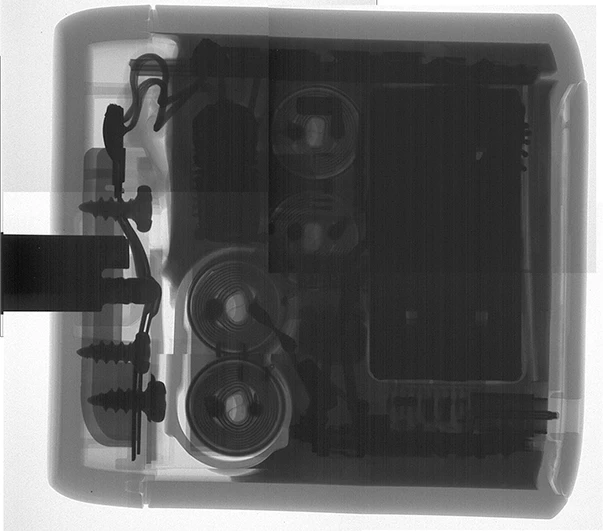

Multiple aluminum electrolytic capacitors are used in USB chargers.

This x-ray photograph shows a 60W-class charger. Four cylindrical components are installed, indicating that aluminum electrolytic capacitors are used.

X-ray photograph of a USB charger

(The cylindrical parts are aluminum electrolytic capacitors)

3. Uninterrupted power supply(UPS)

Data center servers are expected to operate 24 hours a day.

A UPS has a built-in battery, which allows it to continue supplying power to the server and keep it running even during a temporary power outage due to events such as lightning strikes or power line failures.

Although there are various types of UPS, general-purpose models convert AC power to DC before charging the battery. During discharge, they convert the DC supplied from the battery to AC and send it to the server.

Our aluminum electrolytic capacitors are used in AC to DC and DC to AC converters.

4. Server on-board power supply(POL)

Converts the voltage (12/48Vdc) supplied from the power supply (AC/DC) to the optimal voltage for each part inside the server.

Servers use parts with different operating voltages, such as cooling fans, HDDs/SSDs, CPUs, and GPUs.

Conductive polymer aluminum solid capacitors and ceramic capacitors are used to convert 12Vdc to low voltages of 5Vdc, 3.3Vdc, or 1Vdc and lower.

5. GPU-adjacent power source(POL)

Like the CPU, the GPU uses a dedicated power supply stabilization circuit (VRM: Voltage Regulator Module).

Large fluctuations in the power supply voltage supplied to the GPU may cause errors in calculations, so a circuit with high voltage maintenance accuracy is used.

Conductive polymer aluminum solid capacitors and ceramic capacitors are also used here, but there are particularly strict performance requirements for ESR (internal resistance) and ESL (internal inductance).

Our product lineup includes ultra-low ESR products for VRM, which are used around CPUs/GPUs.

Future outlook

1. Compatibility with high-output power supplies

In addition to generative AI, servers for cloud services such as regular data processing are also being installed in high density, creating continuous requirements for high-efficiency, high-output power supplies.

High-voltage power supplies are being considered as one solution to increase efficiency. By increasing the voltage, it is possible to reduce the current (ampere) for the same wattage. By reducing the current, it is possible to make the wiring thinner, and with the same wiring diameter, it is possible to reduce power loss.

- Increase AC voltage beyond 240/277Vac

- Distribute power with several 100Vdc of DC (high-voltage DC power supply)

- Distribute power with 48Vdc of DC (48V DC power supply)

- Increase the voltage line inside the server from 12Vdc to 48Vdc

Evaluations are underway for adopting one or a combination of these solutions.

We have a selection of products to handle any situation.

- Large capacity aluminum electrolytic capacitors compatible with high voltages exceeding 500V

- Large capacity aluminum electrolytic capacitors and inductors exceeding 450V

- Hybrid capacitors with a rated voltage of 63V or higher

2. Thermal cooling

40-50% of a data center's power consumption is used for cooling, and efficient thermal cooling helps reduce power consumption and, in turn, CO2 emissions.

Cooling can be broadly divided into air cooling and liquid cooling (generally called water cooling). Water cooling in particular continues to be developed due to its high cooling efficiency, and in recent years liquid cooling (cold plate) has been put into practical use while liquid immersion is currently under development as a future technology.

i. Liquid cooling(Cold Plate)

This is a method of cooling by circulating coolant within pipes. Electronic components and coolant come into contact through pipes and heat sinks, so there is no direct contact between them.

ii. Liquid Immersion Cooling

This method cools the entire device containing electronic components by immersing it in an insulating and inert solvent. Since the coolant comes into direct contact with electronic components and penetrates to the interior, there are issues that need to be verified, such as long-term reliability.

We are currently developing products compatible with liquid immersion cooling, which is the next generation cooling method.

We have already started shipping samples and will respond to market needs as soon as possible.

For Liquid immersion cooling

The “New Products/Products Under Development” page provides information about the series labeled “Liquid Immersion Cooling Compatible Products”.

We offer a wide range of products from high-voltage products essential for server power supplies to low-resistance (ESR) products that use conductive polymer.

As explained above, the increase in data centers due to advancements in generative AI and cloud computing will create new technological requirements for electronic components such as aluminum electrolytic capacitors.

As a manufacturer with the top global share of aluminum electrolytic capacitors, we contribute to enriching lives and reducing environmental impact by developing technology that anticipates next-generation methods.

Footnote

The images used in the article are illustrations or conceptual diagrams for understanding and may differ from actual equipment.

This page was partially created using generative AI.

*Source: Data Center Market Size, Industry Report on Share, Growth Trends & Forecasts Analysis up to 2029, Mordor Intelligence