Successful Development of the Industry's First Aluminum Electrolytic Capacitors Compatible with Server "Liquid Immersion Cooling".

Nov. 01, 2024RELEASE

Press Release

November 1st, 2024

Nippon Chemi-Con has been working to improve the functionality of aluminum electrolytic capacitors used in servers in order to contribute to the high performance of expanding IT infrastructure. The company has recently succeeded in developing the industry's first products compatible with Liquid Immersion Cooling (LIC), a highly efficient server cooling method, and has started to provide samples.

Recently, there are growing expectations for the expansion of next-generation data centers against the backdrop of the spread of generative AI technology, the promotion of DX in the manufacturing industry, and its use in autonomous driving infrastructures for vehicles.

Meanwhile, AI servers already on the market consume considerably more power than conventional server units due to the higher performance of CPUs/GPUs, and the increased heat generated by individual server units has led to a sharp increase in the demand for air-conditioning power for cooling in data centers. As a result, the power consumption of the data center as a whole has increased. Power consumption in data centers is on the rise and is a global environmental challenge, with carbon neutrality initiatives underway in many countries.

On the other hand, it has been confirmed that immersion of conventional aluminum electrolytic capacitors accelerates the deterioration of the sealing rubber and shortens their operating life due to airtightness failures. Aluminum electrolytic capacitors are used in a wide range of applications on servers, from primary-side smoothing to final-stage CPU/GPU drives, and must be immersion-compatible.

- *1

- PUE = (overall data center energy consumption [kWh]) / (IT equipment energy consumption [kWh])

Typical data center PUE is around 2.0

Taking advantage of its strength in in-house development of sealing rubbers, Nippon Chemi-Con has carried out an evaluation of airtightness resistance to immersion cooling and developed a new sealing rubber (patent pending). The company is also continuing evaluations with the cooperation of major coolant manufacturers.

Nippon Chemi-Con has already received evaluations from some data center-related users using immersion cooling, and it is expected that cooling will be a major challenge in the automotive and industrial equipment markets as well. The company is happy to provide test samples upon request.

Recommended Product Lines

| Category | Type | Series | Characteristics |

|---|---|---|---|

| Conductive Polymer (Al-solid) | SMD |

For liquid immersion cooling |

|

| Conductive Polymer (Al-solid) | Radial Lead |

For liquid immersion cooling |

|

| Conductive Polymer (Al-hybrid) | SMD |

For liquid immersion cooling |

|

| Aluminum Electrolytic | SMD |

For liquid immersion cooling |

|

| Aluminum Electrolytic | Snap-in |

For liquid immersion cooling |

|

Sample ・Mass Production Timing

- Samples for immersion evaluation

- :Available

- Mass production

- :2025

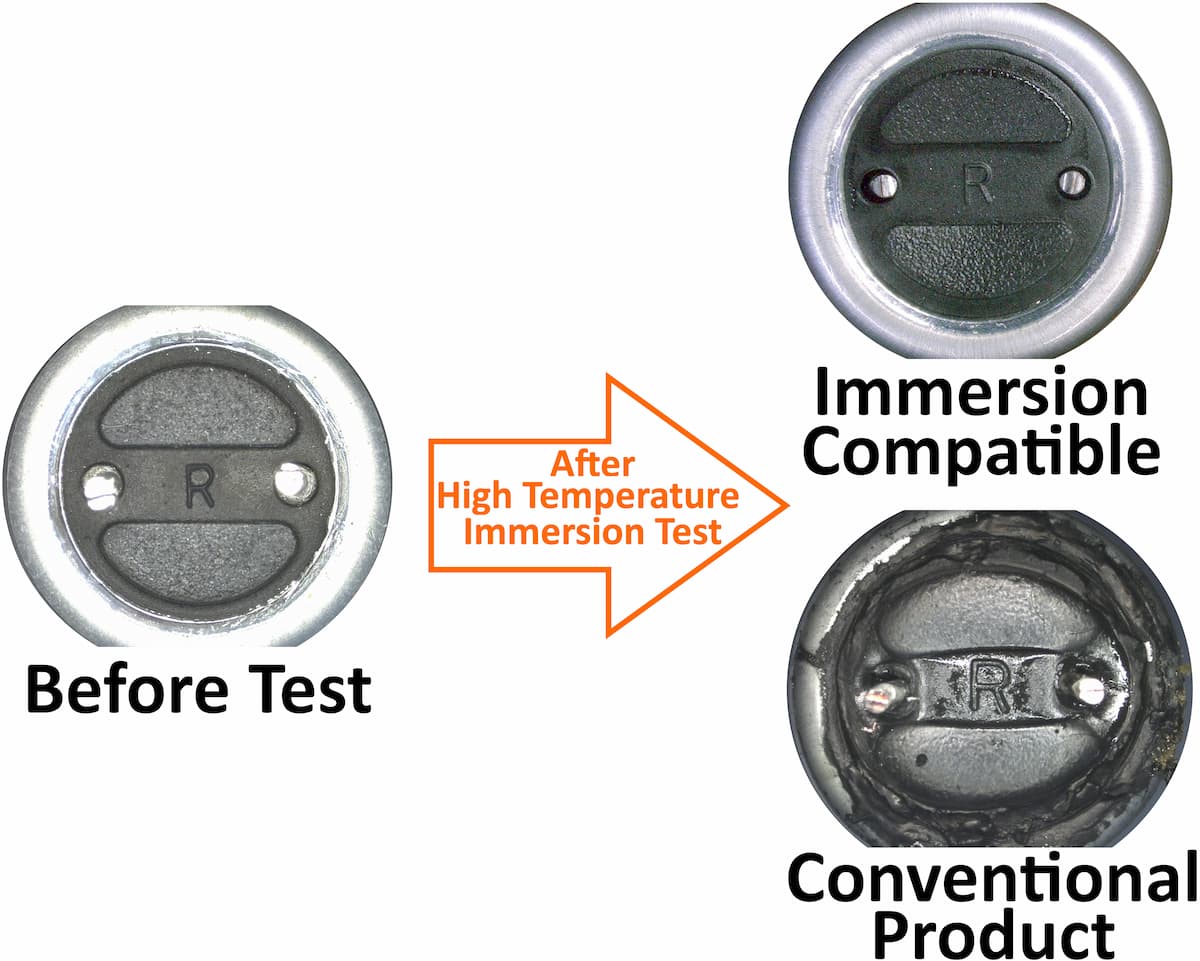

Comparison of Sealing Rubber Deterioration

Fig.1Comparison of appearance after immersion test

Conventional products show swelling and partial melting of the sealing rubber due to coolant penetration, but there is no change in the immersion-compatible product.

Note: Appearance before testing is the same for conventional products and immersion-compatible products, and only immersion-compatible products are shown in the examples.

Fig.2Weight change after immersion test

In a weight change test to evaluate the degree of coolant penetration, the weight of the conventional product increases, but there is no change in the weight of the immersion-compatible product.

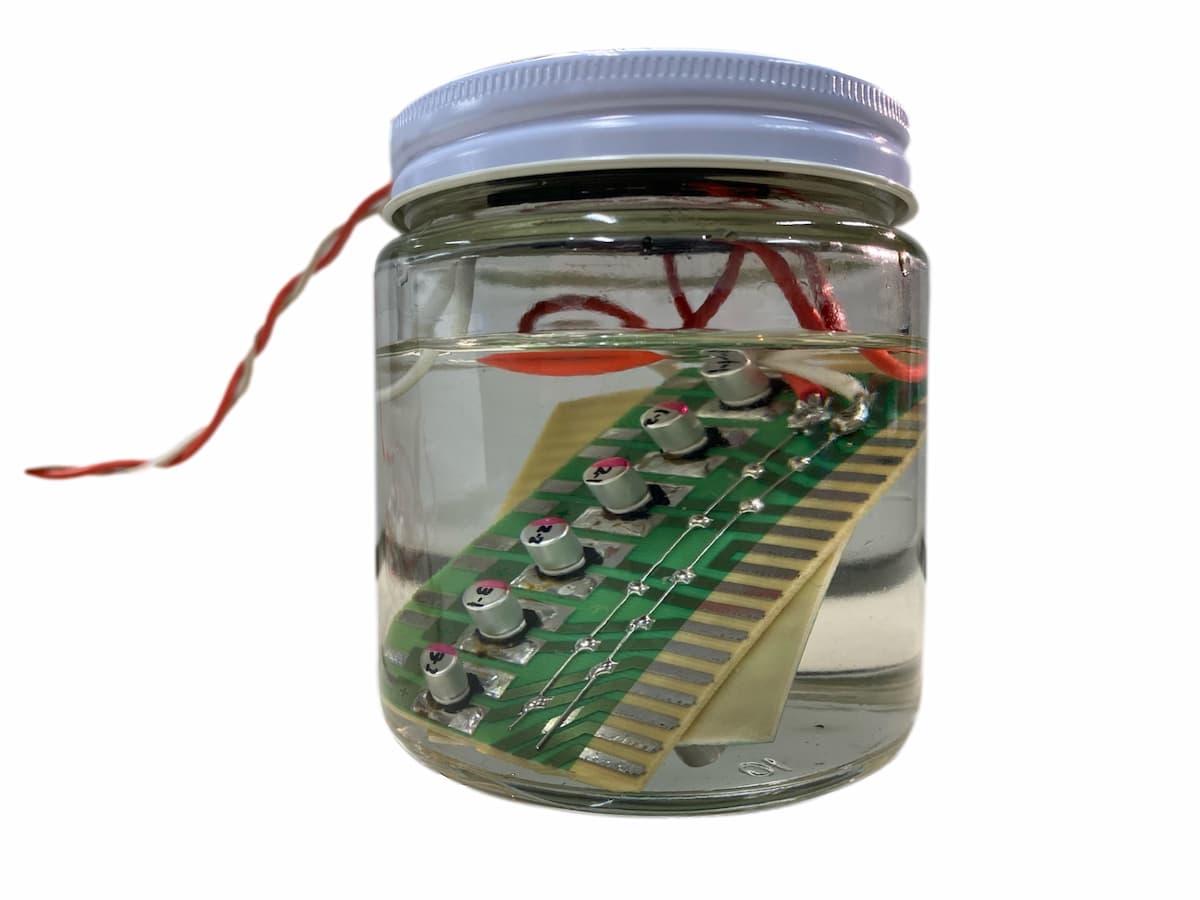

Image of Immersion Test

Fig.3Immersion method used in immersion test

Directly immersed in coolant with electronic components mounted on the PCB.

Aluminum Electrolytic Capacitors Used in the Field of Generative AI

Please use the link below to learn more about the many aluminum electrolytic capacitors used in data centers.

Introduction of Aluminum Electrolytic Capacitors Used in the Field of Generative AI