Basic Knowledge on Supercapacitors

Characteristics of Supercapacitors

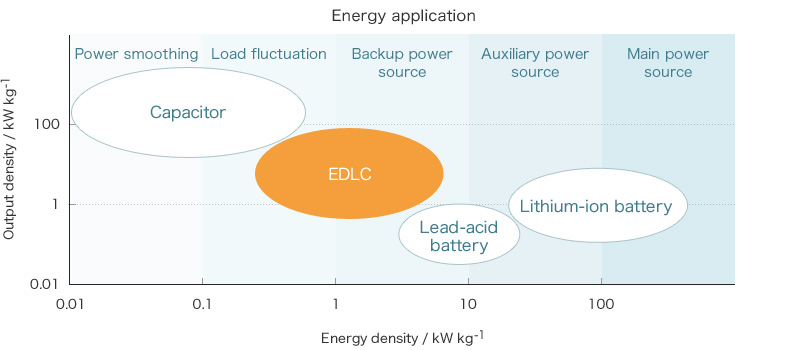

An Supercapacitors, sometimes abbreviated as EDLC, is a storage device that is classified as a capacitor. Compared to another familiar electricity storage device, the rechargeable battery, a capacitor has inferior energy density (amount of energy stored per unit of mass or volume). However, capacitors offer superior output density (volume of instantaneous electricity output per unit of mass or volume). Furthermore, capacitors suffer extremely low performance degradation due to repeated charging and discharging at large currents, meaning they also have superior service life.

A comparison of typical electricity storage devices based on energy density and output density is shown in [Table 1]. Supercapacitors are comprised of a capacitor, such as an aluminum electrolytic capacitor or ceramic capacitor, and features that supplement the characteristics of a lithium-ion battery or other rechargeable battery. In applications requiring more energy, a rechargeable battery is preferable. Conversely, an Supercapacitors is preferable in applications calling for instantaneous recharge or discharge, the endurance against repeated charging and discharging at large currents.

Another characteristic of the Supercapacitors is that it can be discharged completely. Compared to a rechargeable battery, which cannot fully discharge all its energy, the Supercapacitors can release a larger ratio of its stored energy. One identical characteristic of the Supercapacitors and the rechargeable battery is that voltage fluctuates proportionate to changes in stored energy levels. However, Supercapacitors, which can discharge until it reaches zero voltage state, has larger voltage fluctuations that can require voltage stabilization via the use of a power converter (DC/DC converter). At the same time, this characteristic offers the merit of enabling us to accurately ascertain remaining energy levels by measuring terminal voltage.

Main characteristics

- Several million cycles of charging/discharging possible (extra-long service life)

- Large-current rapid charging/discharging possible (high output density)

- Low charging/discharging loss (low internal resistance)

- Full discharge possible (no limits on discharge depth)

- No heavy metals used for structural materials

- Highly safe in emergency situations, won’t malfunction due to external short circuit

Structure of Supercapacitors

From surface-mounted and coin-type capacitors to radial lead-type, laminate-type, and large-capacity screw terminal type products, Supercapacitors available on the commercial market come in a wide variety of shapes and sizes. These products range from compact capacitors with an electrostatic capacity of 1F or less to large-volume products featuring an electrostatic capacity exceeding 2000F.

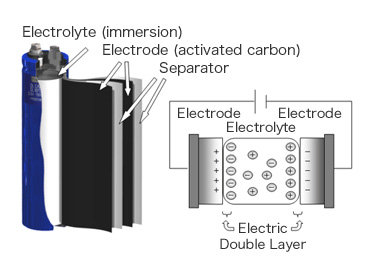

Element structures can largely be divided into two categories: wound types where an electrode shaped into an aluminum foil is wound into a coil, and multi-layered types where the elements comprise a layered structure. While the shapes may differ, the basic electricity storage mechanism and structural principles of both types are basically the same. [Figure 1] shows the internal structure of a large-capacity product formed into a cylindrical shape and its structural principles.

Activated carbon, which has a large specific surface area, is used as the electrode material for Supercapacitors. As shown in [Figure 1], the phenomenon (electric Double Layer) through which electric charges align in extremely short intervals along the electrode/electrolyte interface is used to physically store electricity. Unlike the rechargeable battery, which uses a chemical reaction to store energy, the Supercapacitors stores energy solely via the physical adhesion of ions along the surface of active carbons. This results in a long-lasting product that suffers almost no degradation of structural materials. Taking advantage of this characteristic, Supercapacitors are used as electricity storage devices to reduce replacement frequency or achieve a maintenance-free structure in applications or installation sites where regular parts replacement is difficult (or would result in significant cost increases).

Electrolytes are largely categorized as water-based, organic, or ionic liquids. Typical examples of organic electrolytes used in numerous products include propylene carbonate-based (PC) electrolytes and acetonitrile-based (AN) electrolytes. These two types of electrolytes use different solvents. AN-based electrolytes offer the advantageous characteristic of having a low internal resistance. On the other hand, the low volatility temperature of the electrolyte means there are limitations on the temperature of the usage environment. Furthermore, there is a risk of the toxic cyanide gas being produced if ignited. As such, at Nippon Chemi-Con, we opt to focus on safety and by using non-AN-based organic electrolytes.

Large-capacity Supercapacitors are often used in bank structures, which link multiple cells in a series or parallel array in order to achieve the voltage or electrostatic volume required for the equipment in which the capacitor is installed. Some capacitor manufacturers offer capacitor modules as part of their Standard product line. These modules are comprised of multiple cells combined into a bank structure and an embedded balance circuit that works to prevent voltage inconsistency between each cell. There are also manufacturers who provide specialty modules featuring advanced vibration resistance and shock resistance. These power storage units can be configured with modular connections, making it easy for the user to create prototypes and conduct test installations.

Applications for Supercapacitors

There is a wide variety of Supercapacitors, from compact components with an electrostatic capacity of 1F or less to large-capacity products exceeding 2000F. These capacitors also come in a wide variety of shapes, from surface-mounted types to screw terminal-types.

The applications for Supercapacitors also vary greatly between compact products and large-capacity products. In the small and medium capacity products, a market in which we have a long-established presence, Supercapacitors are used in mobile phones, smartphones, AV devices, toys, and gaming devices. In most of those applications, Supercapacitors are used as backup power supply units for real-time clocks and memory. In OA devices such as printers and projectors, Supercapacitors are used as supplemental power supply units that work to increase performance, including rapid reboot and energy conservation. In recent years, Supercapacitors are being used as a backup power supply for smart meters and future target applications include use as a peak power assist or a camera flash module in smartphones. The market for Supercapacitors is expected to grow as new product development continues.

Conversely, large-capacity products are used mainly for power storage and stabilization, with applications including power assist, backup power source, and energy regeneration. With the growing awareness of energy problems facing society, the development of energy-saving devices that take advantage of the beneficial characteristics of Supercapacitors is accelerating in nearly every industrial sector. While there are examples of power storage devices that only use Supercapacitors, there are numerous examples in which Supercapacitors are combined with rechargeable batteries to create configurations that compliment the properties of each storage technology type. Examples of common implementations for large-capacity products are shown in [Table 2]. Beyond the indicated examples, there are numerous types of implementations in a wide variety of fields and the evaluation of new implementations is accelerating.

DLCAP™, the Supercapacitors manufactured by Nippon Chemi-Con is used in the power storage devices used in vehicle braking energy recovery systems. As the world's first capacitor-based braking energy recovery system used in an automobile, this system contributes to improved fuel economy. Nippon Chemi-Con's DLCAPTM was selected for its combination of safety and high reliability achieved through the use of a PC-based electrolyte and vastly reduced internal resistance made possible by Nippon Chemi-Con's proprietary technology.

The development of Supercapacitors is advancing not only in the direction of low internal resistance, but also towards the development of products able to withstand higher voltages, products with increased capacity, and products with greater heat resistance. As customer needs advance, so does technical innovation. The Nippon Chemi-Con product line includes three types of a screw terminal-type products: the DXE Series, which provides low resistance at high output, the highly heat-resistant DXG Series, and the DXF Series, which is designed to withstand high voltages. Our product line also includes lead terminal-type DKA Series. We also offer capacitor modules equipped with voltage balancing circuits.

As the emphasis on energy management continues to increase in the future, we expect to see the acceleration of development in a variety of fields, including redundant power systems for use in autonomous vehicles, ICT equipment with new functions, energy-saving equipment, storage systems to achieve highly efficient energy use, development to secure power quality in response to the incorporation of natural energy sources, and measures to help stabilize power networks. In these fields and applications, the market for Supercapacitors will continue to grow.

[Table 2] Typical uses of Supercapacitors

| Main applications | Used equipment | Main purpose and benefits |

|---|---|---|

| Power storage | Road markers (solar power + LED) | Wireless designs, zero maintenance |

| Traffic information collection terminals (solar power generation + sensor) | Wireless designs, zero maintenance | |

| LED street lights (solar power generation + LED) | Wireless designs, zero maintenance | |

| Power stabilization | Large-scale low voltage countermeasure devices | Countermeasures against low voltage due to short-time high power consumption (crisis management) |

| Power source assist | Digital multifunction printers (copier) | Energy conservation, shorten warm-up time |

| Backup power source | Power line failure monitoring devices | Signal transmission in a power outage, zero maintenance (crisis management) |

| Emergency disaster response vending machines | Backup power supply in a power outage, storage for manual power generation (crisis management) | |

| Various vehicle-mounted systems | Increased power supply redundancy and toughness | |

| Energy regeneration | Hybrid transfer cranes | Diesel engine size reduction, energy conservation |

| Electric forklifts | Improved operating times with battery assist | |

| Hybrid heavy construction equipment | Diesel engine size reduction, energy conservation | |

| Transport equipment | Fuel economy improvement, CO2 reduction |

Service Life Characteristics of Supercapacitors

Supercapacitors are limited-life devices. Service life will vary depending on usage conditions, including environmental factors such as temperature, humidity, and vibrations, and as well as electrical factors such as applied voltage and charging and discharging conditions. The guaranteed service life of an Supercapacitors is indicated in our catalog under "high temperature load properties".

Ambient temperature and service life

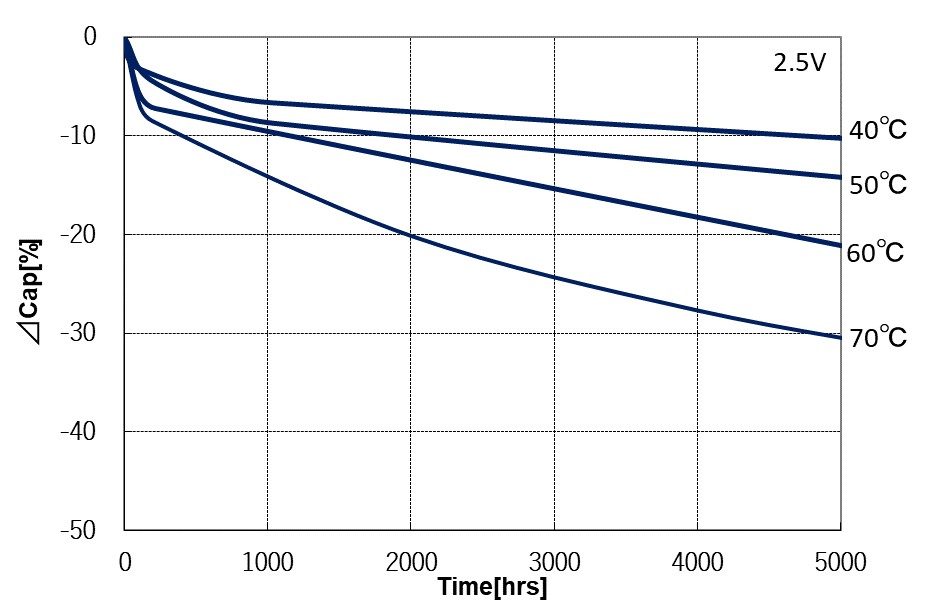

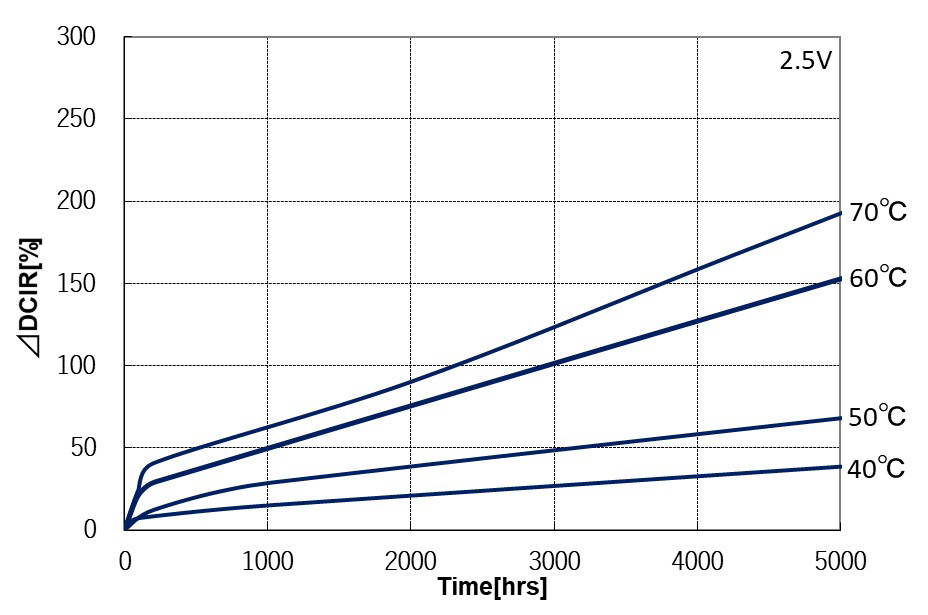

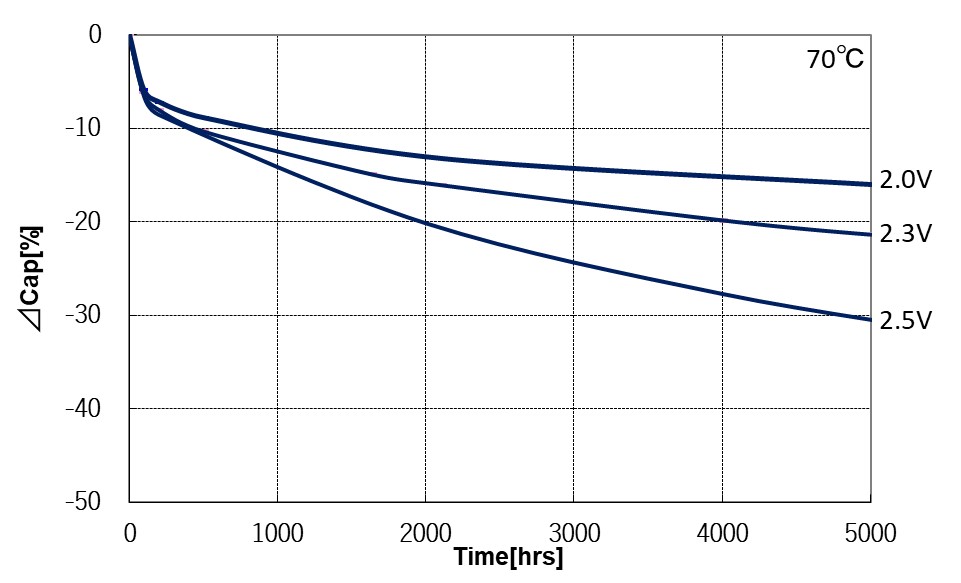

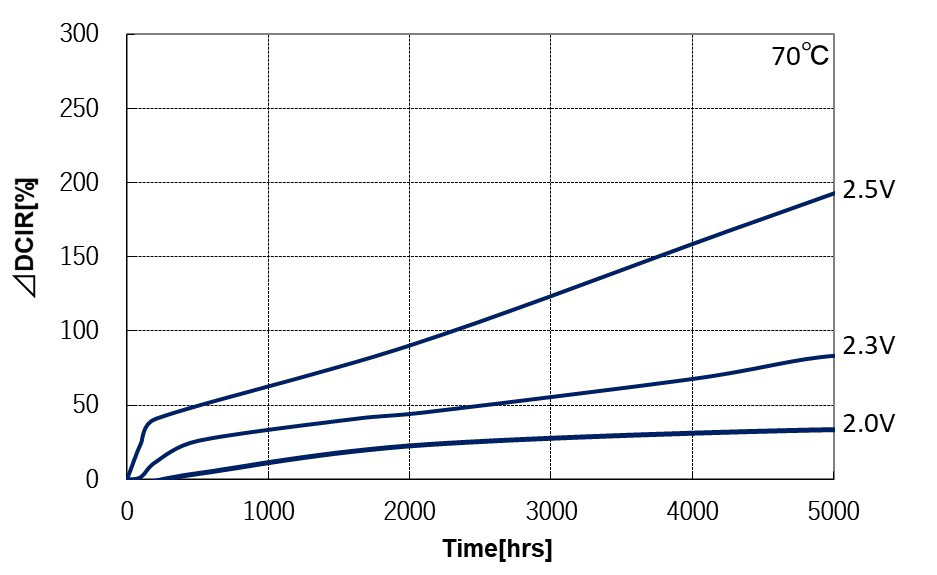

As shown in [Figure 2], the service life of an Supercapacitors is greatly impacted by the ambient temperature of the location of use. Setting the environmental controls to a lower temperature during use can be expected to extend the service life of the product.

[Figure 2] Endurance tests (temperature parameters)

Applying Voltage Effect on Lifetime

As shown in [Figure 3], the service life of an Supercapacitors is greatly impacted by the voltage used on the product. Setting the applied voltage to a lower setting during use can be expected to extend the service life of the product.

[Figure 3] Endurance tests (voltage parameters)

Self-generated heat due to charging/discharging

As Supercapacitors have low internal resistance, charge and discharge current product internal heating, which can impact the service life of the product. In particular, applications requiring continuous charging and discharging at high currents will result in temperature increases that may accelerate deterioration. Generated heat will vary significantly depending on the charge/discharge pattern, so it is necessary to consider temperature increases caused by this generated heat. Furthermore, high current charging/discharging will cause voltage drops so it is necessary to account for this voltage drop.

Service life estimates

As service life acceleration factors for Supercapacitors, heat and continuous voltage application have a significant impact on service life. As shown in [Figure 4], there is a linear correlation between changes in electrical properties and the square root of the test time (√t). This correlation can be expressed as follows.

ΔC=k√t+a

In this forma, "k" represents the service life acceleration coefficient and will vary depending on the temperature and voltage. Determining "k" for relevant implementation conditions will enable you to estimate service life.

"k" and "α" will vary depending on temperature, voltage, and the product series so please contact us for details.

![[Figure 4] Endurance test √t plot example](/products/edlc/images/figKnowledge-plot.jpg)