Conductive Polymer Hybrid Aluminum Electrolytic Capacitor HXK series Developed - Achieves up to 1.2x capacitance and 1.5x the ripple current compared to products of equivalent size

Oct. 27, 2023 RELEASE

Press Release

October 10, 2023

Nippon Chemi-Con is pleased to announce that we have developed the HXK series. The HXK series offers higher capacitance and a higher ripple current compared to the HXJ series of conductive polymer hybrid aluminum electrolytic capacitors.

This series maintains the high reliability of the existing product (HXJ series: guaranteed for 4,000 hours at 125°C; high humidity performance: guaranteed for 2,000 hours at 85°C, 85%RH) while achieving nearly 1.2x higher capacitance and up to 1.5x the ripple current in a product of the equivalent size.

Contributing to vehicle ECU development

From the control of a vehicle’s basic functions, “go, turn, stop”, to assisting safe and pleasant driving, vehicle ECU are indispensable. With the integration of various functions moving forward, there is demand for size reductions, high integration, and compatibility with high power applications. This trend is particularly strong for the ECU used in the increasingly complex control and configuration systems of EVs and HVs. This is also leading to a need for equivalent performance improvements in the capacitors mounted in ECU. The HXK series fulfills such demands by helping maximize the performance of ECU.

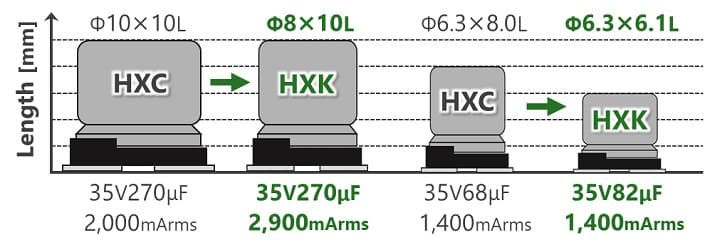

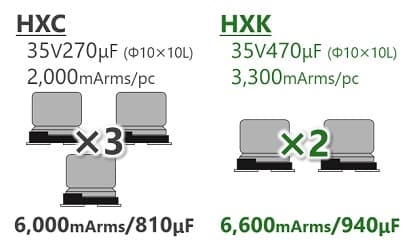

In addition to offering the largest capacitance in the industry, this series also achieve a high ripple current. Compared to existing products (HXC series), this product maintains capacitance and ripple current performance while offering significant reductions in product size (see figure below). This series will contribute to increased vehicle performance by enabling low-profile, space-saving ECU unit designs featuring thinner boards with a reduced mounting area and fewer parts.

<Example of mounting area reduction, lower profile, and parts reduction>

Technical Features

Using an electrolyte in conductive polymer hybrid aluminum electrolytic capacitors comprised of a conductive polymer and an electrolyte liquid achieves low ESR properties and superior heat resistance thanks to the conductive polymer. At the same time, the electrolyte liquid adds oxide layer repairability. Through this combination, we have achieved high voltage products that offer low ESR and high reliability.With the HXK series, the anode foil is comprised of a high capacitance foil we developed in-house to optimize the opposite electrode foil. At the same time, using a conductive polymer material offering good compatibility with both foils enables a design that maintains high reliability while achieving high capacitance and a high ripple current.

Product Specifications

- Category temperature range: -55°C to +125°C

- Rated voltage range: 16 WV, 25 WV, 35WV

- Capacitance range: 82µF to 1,000µF (capacitance tolerance ±20%)

- Case sizes: ⌀6.3mm×5.8mmL to ⌀10.0mm×10.0mmL

- Endurance: 4,000 hours at 125°C

- Moisture resistance: 2,000 hours at 85°C85%RH

Samples and Mass Production

- Samples: January 2024

- Mass production: April 2024

Production Sites

Chemi-Con East Japan Corp. Miyagi PlantList of Standard Products

| Size ⌀D×L [mm] |

Rated voltage [Vdc] |

Cap. [μF/120Hz] |

Endurance [hrs.] 125℃ |

ESR [mΩmax/100kHz] |

Rated ripple current [mArms/100kHz] |

|||

|---|---|---|---|---|---|---|---|---|

| HXJ | HXK | HXJ | HXK | HXJ | HXK | |||

| 6.3×5.8 | 16 | 150 | 180 | 4,000 | 45 | 45 | 1,080 | 1,500 |

| 25 | 100 | 120 | 50 | 50 | 1,300 | 1,400 | ||

| 35 | 68 | 82 | 60 | 55 | 1,200 | 1,400 | ||

| 8.0×10.0 | 16 | 470 | 560 | 4,000 | 20 | 20 | 2,000 | 3,000 |

| 25 | 330 | 390 | 22 | 22 | 2,000 | 2,900 | ||

| 35 | 220 | 270 | 22 | 22 | 2,000 | 2,900 | ||

| 10.0×10.0 | 16 | 820 | 1,000 | 4,000 | 18 | 18 | 2,800 | 3,400 |

| 25 | 560 | 680 | 20 | 20 | 2,800 | 3,300 | ||

| 35 | 390 | 470 | 20 | 20 | 2,800 | 3,300 | ||

Product Appearance